Choosing the Right Stretch Film: Cast vs. Blown Stretch Wrap Explained

Stretch film, also called pallet wrap, is one of the most widely used packaging materials in industries across the USA. It is made from low-density polyethylene (LLDPE), which gives it flexibility, durability, and strength. Businesses use it to wrap pallets, secure shipments, and protect goods during transit. It can easily stabilize loads, reduce product movement, and safeguard items from dust and moisture. At A.N.S Plastics Corporation, we provide high-quality stretch wrap that is economical, durable, and 100% recyclable.

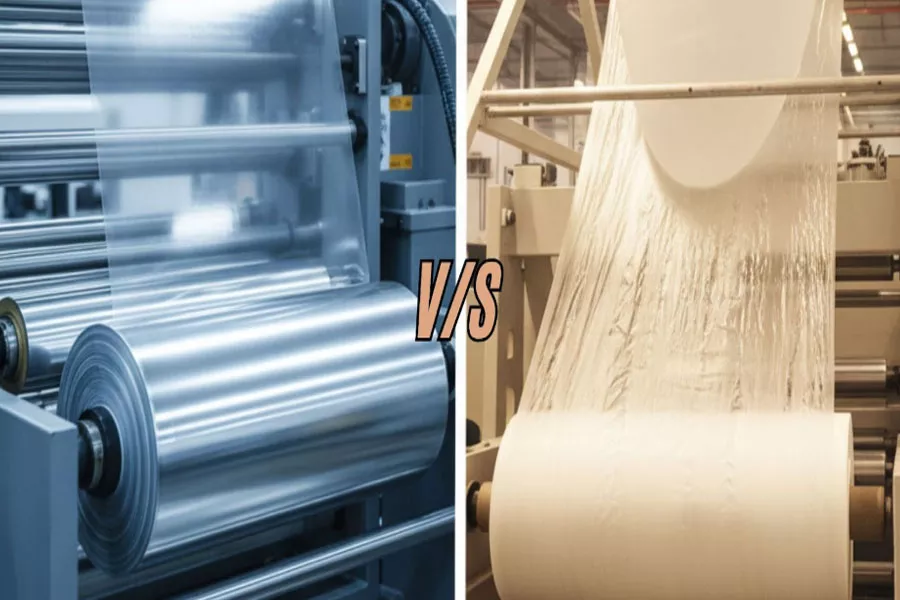

Based on different manufacturing methods, stretch films are of two types: Cast stretch wrap and Blown Stretch wrap. The major differences between the two lie in their manufacturing processes, which result in variations in usability and price. If you want to know their differences and how to choose the most suitable stretch wrap, continue reading this blog, in which our expert will guide you to make the right choice.

Cast vs. Blown Stretch Film Manufacturing

Both cast and blown stretch films are made from polyethylene, but they differ in their manufacturing processes and performance characteristics. Cast stretch film is produced through a cast extrusion process, which makes it clear, smooth, and quiet to apply. On the other hand, blown stretch film is made using a blown extrusion process, which gives it greater strength, higher memory, and excellent puncture resistance. Understanding these differences will help you choose the right film for their needs and prevent costly mistakes in packaging.

Cast Stretch Film Explained

Cast stretch film is popular because of its high transparency and ease of use. People can see through it, which makes scanning barcodes quick and straightforward. It unwinds quietly, which is useful in busy warehouse environments. Besides, it stretches more, enabling workers to wrap more pallets with less film. However, because it stretches easily, it offers less holding power compared to blown film. Cast stretch film is often the best choice for uniform loads, high-speed wrapping, and environments where visibility matters. Its smooth texture also allows layers to cling well without sticking excessively.

What is Blown Stretch Film?

Blown stretch film is valued for its strength and toughness. It has higher puncture resistance, making it ideal for wrapping irregular or sharp-edged loads. It also has stronger load retention because it does not re-stretch after being applied. Its memory allows it to shrink back tightly, keeping loads secure even under stress.

However, blown film is noisier during the application process. Besides, it is not as transparent as cast film. It also yields less stretch, requiring more material per pallet. Despite this, it remains the go-to choice for heavy-duty, long-distance, or outdoor shipments where strength and durability are most crucial.

Which Type of Stretch Wrap Is Better?

Whether you should select a cast or a blown stretch film depends on the packaging situation. You need to consider factors such as load type, wrapping speed, durability requirements, and storage conditions. Cast stretch wrap works well for lighter loads and shipping products that prioritize visibility and efficiency. Blown film is better suited for challenging conditions, heavy or irregular loads, and shipping where strength is critical. Businesses can save costs and reduce risks by selecting the right film type for their unique operations. Understanding the trade-offs between yield, clarity, and resistance enables companies to optimize their packaging choices.

7-Point Comparison Chart

| Factor |

Cast Stretch Film |

Blown Stretch Film |

| Load Retention |

Load Retention Stretches easily, which can cause shifting |

More holding power, won’t re-stretch once applied |

| Film Memory |

Minimal shrinking back to the original state after stretching |

Higher shrinking back to the original size after stretching |

| Film Yield |

More stretch to wrap more pallets with less film |

Less stretch requires more film to wrap pallets |

| Puncture Resistance |

Standard tearing can occur with high stress |

Greater resistance to breaking |

| Cling of the Film |

2-sided cling allows pallets to stick together |

1-sided cling for higher load retention |

| Visual Clarity |

Perfectly clear, easy to scan and read, higher gloss creates reflections |

Not crystal clear, difficult to scan and read, low gloss reduces reflections |

| Noise of Unwind |

Very quiet when releasing from the roll |

Loud when releasing from the roll |

This comparison highlights that both films have their advantages. Cast film is transparent, quiet, and cost-efficient, while blown film offers unmatched durability, memory, and puncture resistance. The choice ultimately depends on the load type and shipping environment. Companies should weigh these factors carefully before deciding which option works best for them.

Matching Film With Your Application

Every packaging operation is different. A warehouse shipping light products in large volumes might prefer cast film to save time and cost. A manufacturer transporting heavy or sharp-edged machinery would benefit more from the durability of blown film. Outdoor shipments that face harsh weather also require the strength of blown film. Therefore, businesses must assess not just the film cost but also the risks of damaged goods and delays. The right stretch wrap reduces losses and supports smoother supply chain operations while also improving customer satisfaction.

Order Online From Us the Most Suitable Stretch Wrap

The debate between cast and blown stretch film is not about finding a single winner; rather, it is about understanding the advantages and disadvantages of each. It is about finding the right fit for each application. Cast film delivers visibility, efficiency, and savings in controlled packaging environments. Blown film provides resilience, strength, and secure retention for challenging shipments. If you find it difficult to choose the suitable stretch film, let our experts guide you in selecting the best option for your needs. With the right stretch film, packaging becomes not just protective but also cost-effective and efficient across industries. Making informed decisions about packaging materials allows businesses to reduce risks, save money, and improve operations.